Description

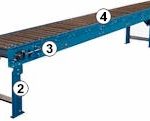

Dual Chain Driven Roller Conveyor – Model CDDB26

NuTech’s Dual chain driven roller conveyors provide a positive drive for handling heavier loads of castings, totes, and pallets. Its rugged construction allow for use in wet, oily, and contaminated applications… This model uses 2.625″ diameter 7 gauge rollers allowing a capacity of 1,000 lbs per foot when supported on 5ft centers.

Roller Centers: 2.812” with 40A21 sprockets. 3.00” with 60A15 sprockets.

Effective Widths: 13”, 19”, 25”, 31”, 37”, 43”, 49”, 54”, 57”, and 61”. Also available from 6” to 61” in 1” increments.

Lengths: Even increments of the roller centers up to 50’. Length also limited to 75 rollers on each side of the drive.

Drive: Standard D10 – bottom, located near center. Drive has cast iron worm gear speed reducer with a standard M03 3/4 H.P. 230/460 TEFC motor.

Speed: Standard 30 feet per minute. Also available from 1 to 120 feet per minute.

Rollers: Standard 2607; 2.625 dia., 7 ga. wall tubes with 11/16” hex cold rolled steel axle, spring retained. Standard A51 bearing are grease packed.

Frames: Standard F22 6” x 1-1/2” x 3/16” channel with bolted 5” x 1-1/2” x 3/16” crosstie.

Chain Covers: 1/8” steel with two piece construction for easy access to chain loops.

Supports: SPHH style adjustable set for standard 36” top of rollers located on nominal 5’ centers. Also available from 11” to 42” top of roller at no additional charge.

Capacity: Up to 1,000 lbs. per lineal foot of conveyor with supports on 5’ centers. Several factors affect conveyor capacity. Consult factory to evaluate specific applications.

Roll Covers: Standard V98: No Roll Cover.

Finish: Standard PP94: Safety Blue, Epoxy Powder Coat.